In 3D printing, the slicer you use is just as important as your printer or filament. It’s the software layer that translates your design into something your printer can understand, making the difference between a successful print and a failed one. Among the most popular slicers in the community are Orca Slicer, Cura, and PrusaSlicer. Each has its own identity, strengths, and limitations.

This article takes a hands-on, human-first approach to comparing these tools. Whether you’re a beginner trying to avoid a rough start or a seasoned user demanding precision, this guide will help you choose the right slicer for your unique setup.

Orca Slicer vs Cura vs PrusaSlicer:

| Feature | Orca Slicer | Cura | PrusaSlicer |

| Ease of Use | Beginner-friendly | Moderate; can be overwhelming | Complex; suited for experienced users |

| Slicing Speed | Very Fast | Moderate | Slower but precise |

| Print Quality | High | Good | Excellent |

| UI Design | Clean and minimal | Functional but cluttered | Feature-rich but dense |

| Plugin Support | Limited | Extensive | Minimal |

| Material Compatibility | PLA, ABS, PETG, TPU (customizable) | Supports nearly all filaments | Optimized for Prusa, supports others |

| Multi-Material Printing | Basic | Good | Excellent (MMU supported) |

| Adaptive Layer Height | Not available | Available | Available |

| Tree Supports | Yes | Yes | Yes |

| Ironing Feature | Yes | Yes | Yes |

| Custom G-code Scripting | Limited | With plugins | Advanced scripting supported |

| Supported File Formats | STL, 3MF, G-code | STL, OBJ, AMF, 3MF | STL, OBJ, 3MF |

| Printer Compatibility | Broad; best with Bambu/Klipper | Broad; supports many third-party | Best with Prusa; supports custom |

| Best For | Beginners, Speed, Modern UI | Hobbyists, Customization | Professionals, Precision Printing |

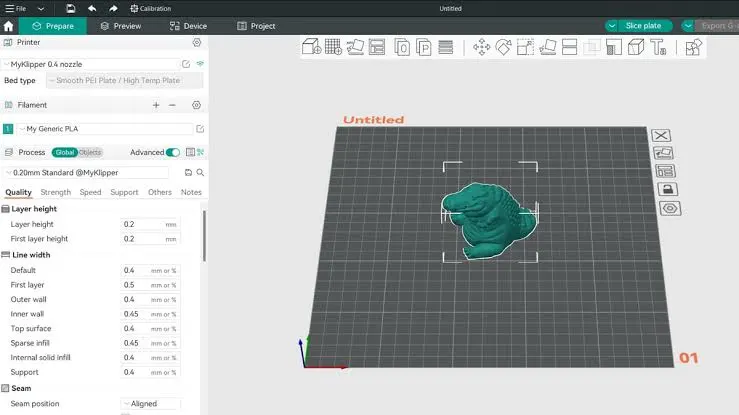

Orca Slicer: Streamlined Speed Meets AI Intelligence

Orca Slicer stands out as a newer player built on the foundation of Bambu Studio but with its own enhancements. It’s focused on automation, intelligent slicing, and faster workflows, making it ideal for high-speed 3D printing setups like those using Klipper firmware or Bambu Lab machines.

It provides features like automatic flow calibration, pressure advance settings, and intuitive presets that reduce the learning curve.

Key strengths:

- High-speed slicing performance optimized for advanced hardware

- Intuitive interface with a clean layout

- Ability to import Cura profiles for smoother migration

- Smart calibration tools like input shaping and flow tuning

Limitations:

- Limited plugin support compared to competitors

- Still growing, which means occasional bugs or incomplete features

For those seeking a modern, fast, and easy-to-navigate slicer that improves with every update, Orca Slicer is an excellent choice.

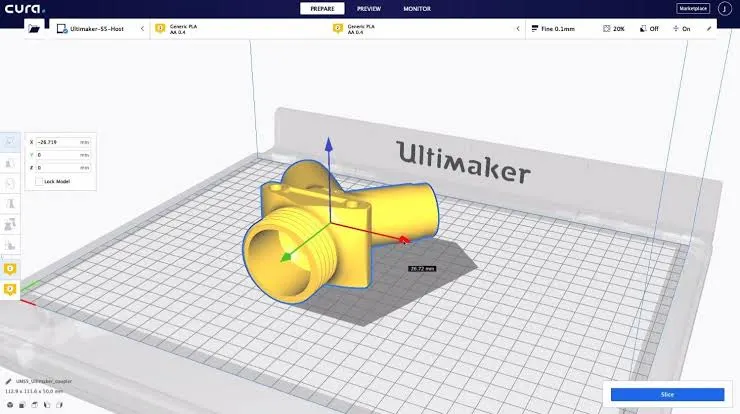

Cura: Feature-Rich and Customization-Friendly

Cura, developed by Ultimaker, is perhaps the most recognized name in slicers. It appeals to users who enjoy fine tuning every setting, thanks to its expansive plugin system and deep configuration capabilities.

Cura’s greatest strength lies in its balance between flexibility and compatibility. It supports nearly every 3D printer on the market and offers adaptive slicing techniques that help improve surface quality.

Main benefits:

- Vast plugin ecosystem for advanced customization

- Wide printer and filament support out of the box

- Adaptive layers and ironing options for better surface finish

- Consistent updates backed by a large community

Challenges:

- Steeper learning curve due to overwhelming options

- Slower slicing speeds on complex models compared to Orca Slicer

If you’re someone who likes to have control over every detail, Cura is a powerful tool. It may not be the easiest to learn, but its capabilities make the time investment worthwhile.

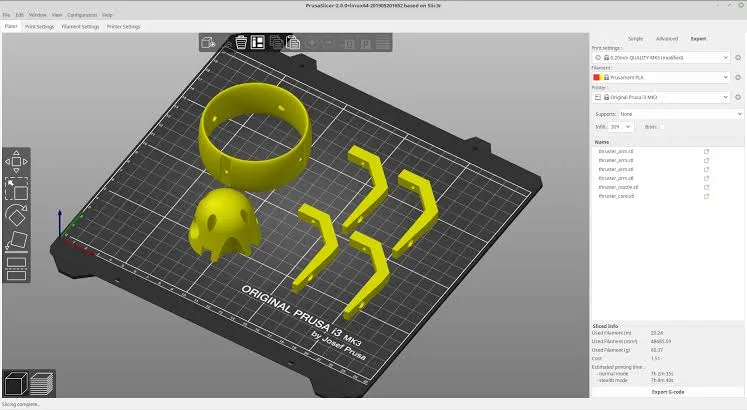

PrusaSlicer: Built for High-End Precision and Multi-Material Printing

PrusaSlicer is the official slicer from Prusa Research, but it has grown into a robust platform that supports both FDM and SLA printing. What makes it unique is its laser focus on output quality and advanced control over print behavior.

It offers precise adaptive layer control, highly tunable supports, and multi-material support that outperforms most alternatives. Professionals and enthusiasts who care about consistency and detail typically gravitate toward PrusaSlicer.

Noteworthy features:

- Superior adaptive layer height adjustment for detailed prints

- Seamless integration with Prusa printers and MMU systems

- Extensive customization of supports, print settings, and paths.

- G-code scripting for advanced users

Drawbacks:

- Complex interface not ideal for first-time users

- Optimized more for Prusa printers than others (though custom profiles help)

PrusaSlicer is best suited for those seeking top-tier quality and flexibility, especially in multi-material or professional applications.

User Experience and Interface Clarity:

Interface plays a huge role in how fast you can start printing and how often you make mistakes. Some slicers lean toward a minimalist approach, while others try to expose every setting.

Ease of Use Comparison:

- Orca Slicer has a clean, accessible interface and minimal clutter.

- Cura offers a middle ground with grouped settings but can overwhelm new users.

- PrusaSlicer is detailed and powerful but requires more technical familiarity.

Users who value simplicity should lean toward Orca. Those willing to learn for more power may prefer Cura or PrusaSlicer based on their needs.

Performance: Speed and Stability in Real Use

The slicing engine’s speed and how well the software handles complex models are crucial when handling larger projects or frequent prints.

Performance observations:

- Orca Slicer is fast and handles large files without major slowdowns.

- Cura performs decently but can lag on high-detail models.

- PrusaSlicer is slower to process but generates optimized tool paths that improve print quality.

If slicing time is a bottleneck in your workflow, Orca Slicer may offer a noticeable upgrade. However, those who prioritize output quality above all may find the extra processing time in PrusaSlicer worth the wait.

Print Output Quality and Feature Depth:

All three slicers can produce excellent prints, but they differ in how they achieve this and how much control they offer.

Orca Slicer excels in:

- High-speed prints with good dimensional accuracy

- Smoother calibration for extrusion

Cura is strong in:

- Surface finish optimization with adaptive layers

- Tree supports and ironing for visible layers

PrusaSlicer leads in:

- High-detail layer control

- Multi-material management

- Resin printing with SLA support

For hobbyists and everyday prints, Cura offers a good balance. For high-detail, functional, or showcase parts, PrusaSlicer often produces the best results.

Format Compatibility and Ecosystem Fit:

Working with standard file formats and importing settings from other slicers is a huge convenience factor.

Format and Compatibility:

- Orca Slicer supports STL, 3MF, and G-code and can import Cura profiles directly.

- Cura supports the widest array of formats including OBJ, AMF, STL, and 3MF.

- PrusaSlicer also supports STL, OBJ, and 3MF, with some features exclusive to Prusa hardware.

For working with different printers and software environments, Cura remains the most flexible. Orca’s ability to pull in Cura profiles is a welcome bridge for migrating users.

Conclusion:

Each slicer in this comparison excels in its own category. There is no universal winner. If you’re after speed and modern calibration, go with Orca. If you need granular control and community tools, Cura is your match. If you require absolute precision and professional results, PrusaSlicer is hard to beat.

FAQs:

Yes, Orca supports many FDM printers, including those running Klipper or Marlin firmware. It offers broad compatibility.

Yes, Orca Slicer allows importing Cura profiles as JSON files, making transitions smoother for experienced users.

Orca Slicer is ideal due to its simple interface and automated calibration tools. Cura also has basic modes for new users.

Yes, while it’s optimized for Prusa models, it supports custom printer profiles for other popular brands.

Cura leads in customization thanks to its plugin system, allowing users to tailor nearly every part of the slicing process.